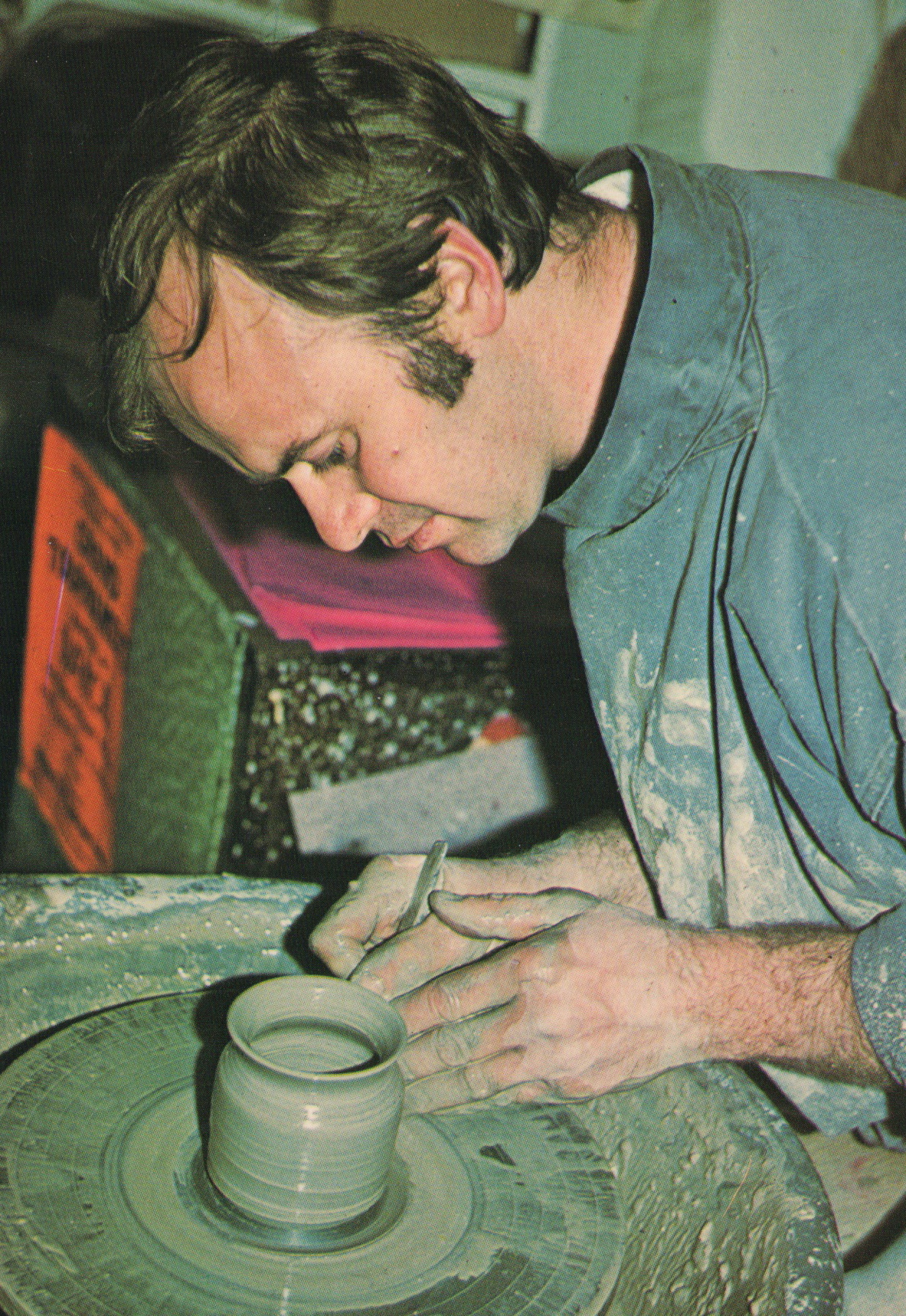

The majority of my designs are hand thrown using white stoneware clay. There are a multitude of steps taken to produce each pot. The first of which is clay preparation.

The next step is to accurately throw the the pot. I usually have several pots in various stages of completion at any given time. Depending on the design there are many processes to to be completed before the first (bisque) firing of the pots.

Pots such as bowls or vases are turned upside down to trim surplus clay from them once they reach a leather hard stage Other pots may have sections removed with the aid of a sharp scalpel to create cut-out or pierced designs, this is also done at the leather hard stage and any cut areas have to be thoroughly sponged to remove any sharp edges.

Pots are thoroughly dried before they are "fired" in the kiln,. The firing process has two stages, stage one the bisque firing, prepares the pots for glazing, the second and final stage takes place after glaze has been applied by dipping, brushing or splashing glaze onto the pot. I fire in an electric kiln to 950c for a bisque firing and 1230c for a glaze firing. Opening the kiln invariably creates anxiety as well as eager anticipation as the final glaze effect may depend on where pots have been placed in the kiln. It is of course very satisfying when pots look as beautiful as I imagined when making them.

A younger me!